The final milestone in the DCS Monitor II project was reached with a successful measurement campaign at the Lubmin interim storage facility.

The Institute of Process Engineering, Process Automation and Metrology (IPM ) can now look back on over twenty years of activity in nuclear safety research projects. Although current national energy policy is clearly aimed at moving away from nuclear energy and fossil fuels as an energy source, this chapter in Zittau's research history is far from over: The dismantling of nuclear facilities and the associated interim storage and subsequent disposal of nuclear waste will remain on the agenda of power plant operators, institutions for the interim storage of radioactive waste, experts, other companies and research institutions for some time to come.

The DCS Monitor I and II project series presented here, which is being carried out by the HSZG in close and proven cooperation with the TU Dresden, has a corresponding thematic orientation. The predecessor project DCS-Monitor I dealt with the evaluation of various physical measurement principles, procedures and methods with regard to their suitability for non-invasive condition monitoring of the inventory of transport and storage containers (TLB) with radioactive materials. Building on these results and findings, the researchers set about developing a practical monitoring procedure specifically for CASTOR casks in the current DCS-Monitor II project, which began in April 2020.

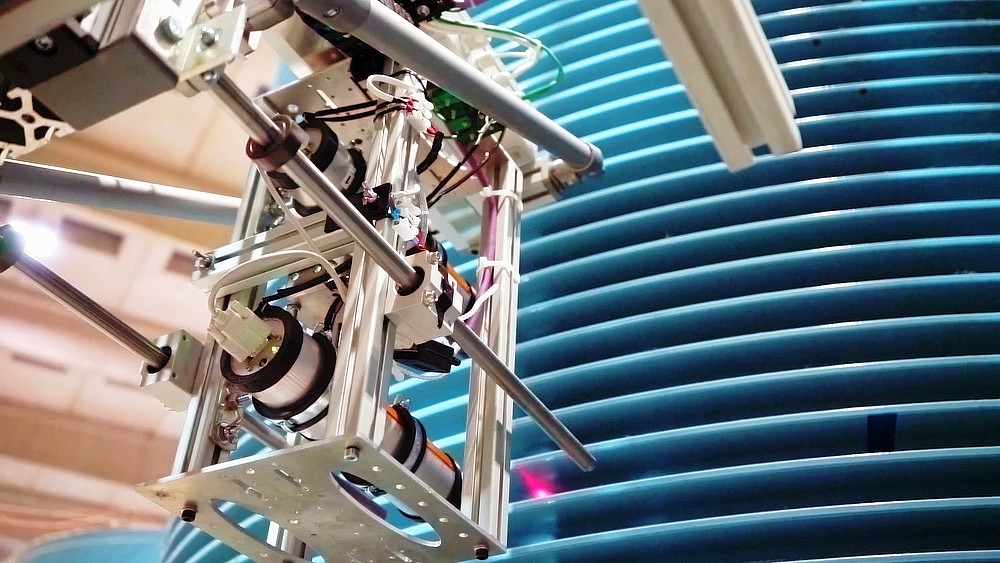

The HSZG project team member, Mr. Sebastian Reinicke, was mainly responsible for the design and construction of a robot equipped with a gamma and neutron radiation measurement system. The radiation measurements on the container shell were to be carried out automatically, i.e. without any human intervention. This requirement has its origins in the German Atomic Energy Act, which defines, among other things, that "precautionary protection against the dangers of nuclear energy and the harmful effects of ionizing radiation" must always be ensured. In particular, this includes keeping the radiation exposure of people as low as possible.

Over the past few months of project work, the measuring robot has increasingly taken shape in one of the IPM's laboratories. The final milestone was the recent measurement campaign on an original Castor container of type 414/84. This was carried out with the support of Entsorgungswerk für Nuklearanlagen GmbH (EWN). The location of the campaign was the EWN's northern interim storage facility in Lubmin, where 74 CASTOR casks containing highly radioactive waste are stored. Over the course of several weeks, automated measurements were carried out on a cask that had been loaded with both low- and high-level spent fuel elements more than 15 years ago. During this period, even the North German Broadcasting Corporation (NDR) did not miss the opportunity to visit the site, conduct an interview and report objectively on the measurement campaign.

Measuring robots examine Castor containers in Lubmin

06.06.2024 ∙ Nordmagazin ∙ NDR

Although the evaluation and interpretation of the measurement data will still take several months of project work, the smooth operation of the measurement robot and the plausibility of the recorded measurement values already allow the conclusion that the system has proven itself and the measurement campaign can be considered a complete success. The best conditions are therefore in place to continue these research and development activities and ultimately to look forward to the practical use of the fully automated measuring system in interim and possibly final storage facilities.

Text: André Seeliger

Image: EWM / Carla Schmidt