The visit by the Federal Office for Radiation Protection to the HSZG focused on the precise detection of radioactive particles.

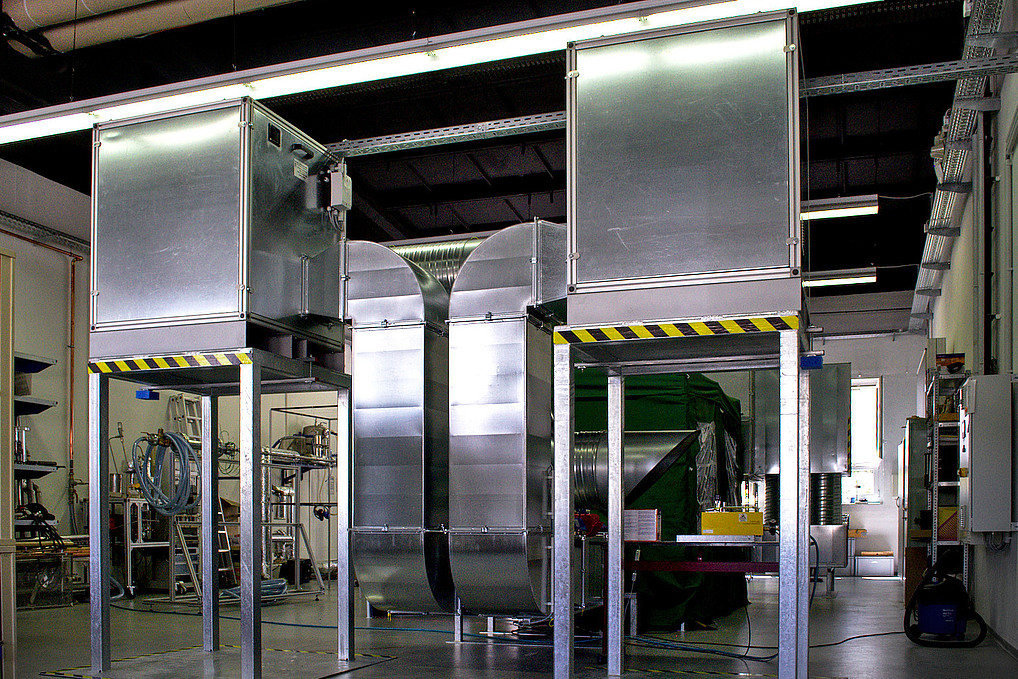

The Institute of Process Engineering, Process Automation and Metrology (IPM) is making an important contribution to the safety of nuclear waste disposal as part of the conversion of the former iron ore mine "Schacht Konrad" for the storage of low- and intermediate-level radioactive waste. To this end, a model of the exhaust air facility in Zittau was scaled down to a fifth of its original size by March 2019. State-of-the-art flow measurement methods are used there to investigate the behavior of particles sucked into the duct.

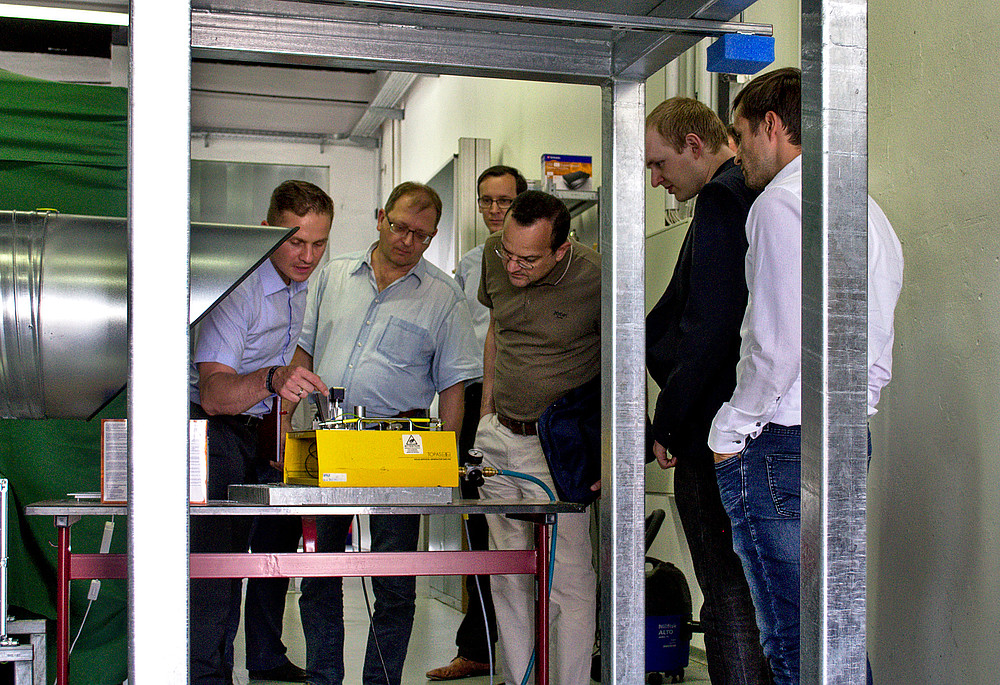

On July 2, the Federal Office for Radiation Protection (BfS) and the project partners, the Federal Company for Final Disposal (BGE) and VPC GmbH, visited the facility. The guests were impressed by the expertise and extensive laboratories for research and teaching in the fields of reactor safety, interim and final storage and radiation technology.

Prof. Alexander Kratzsch, head of the project and director of the IPM, first welcomed the guests and opened the meeting. Following the introduction of the participants and the facilities, the BGE once again emphasized the motivation behind the project. The selected measuring position for the detection of possible radioactive particles must allow representative sampling and thus reliably detect existing elements in the exhaust air.

If radioactive particles are detected in the exhaust air, appropriate countermeasures can be initiated. The results of the experiments in the model channel will determine how the flow control and sampling in the original system in the "Konrad Shaft" will be carried out.

The results of the experiments and the installation of the PIV (Particle Image Velocimetry) measurement technology were presented by Dr. Clemens Schneider (IPM project manager). PIV is a process in which particles are introduced into a flow and the movement of the particles is recorded using successive images, thus depicting the velocity distribution in the flow.

The project partners were able to follow the associated experiments live during their visit.

The IPM's expertise in the fields of thermohydraulics and flow measurement technology as well as its many years of experience with high-resolution imaging measurement methods were the decisive factors in awarding the project to Zittau.

In order to present the guests with the full range of activities in teaching and research in the field of radiation and nuclear technology, Dr Schneider organized the following additional program items:

Many thanks to our guests and all participants for the visit and the constructive discussions, also on the subject of future training opportunities in the field of radiation technology and radiation protection at the HSZG.

Text: Kristin Sprechert, Clemens Schneider